Akụkụ shei buru ibu, nke nwere obere mgbidi na-adị mfe ịgbagha na nrụrụ n'oge a na-arụ ọrụ. N'isiokwu a, anyị ga-ewebata ihe mkpuchi okpomọkụ nke akụkụ buru ibu na nke dị mkpa iji kwurịta nsogbu ndị dị na usoro nhazi mgbe niile. Na mgbakwunye, anyị na-enyekwa usoro kachasị mma na ngwọta nrụnye. Ka anyị ruo ya!

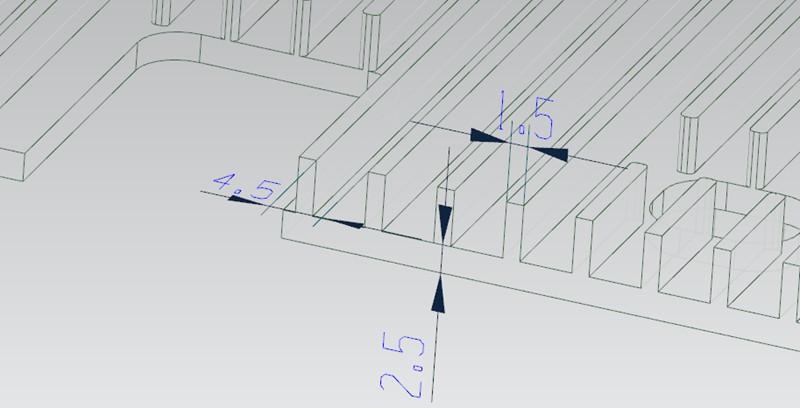

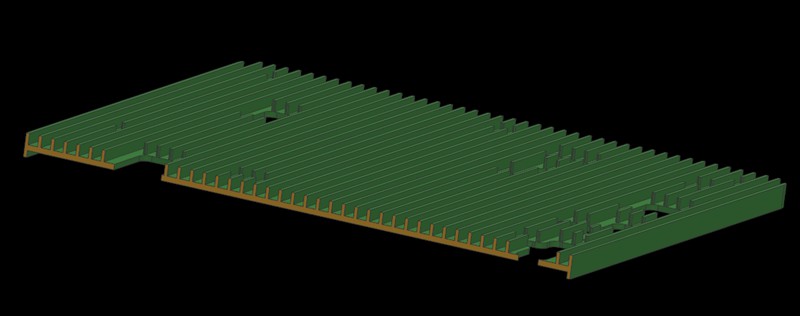

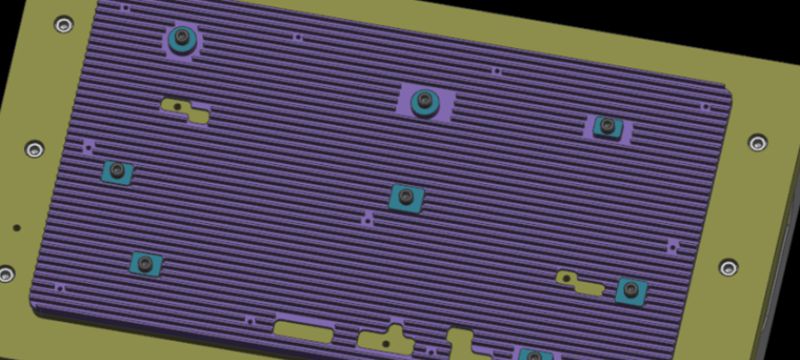

Ikpe ahụ bụ maka akụkụ shei mere nke ihe AL6061-T6. Nke a bụ akụkụ ya kpọmkwem.

N'ozuzu akụkụ: 455*261.5*12.5mm

Nkwado ọkpụrụkpụ mgbidi: 2.5mm

Ọkpụrụkpụ Okpomọkụ: 1.5mm

Okpomọkụ oghere oghere: 4.5mm

Omume na ihe ịma aka na ụzọ usoro dị iche iche

N'oge a na-arụ ọrụ CNC, ihe owuwu shei ndị a nwere obere mgbidi na-ebutekarị nsogbu dị iche iche, dị ka mgbagha na nrụrụ. Iji merie nsogbu ndị a, anyị na-agbalị ịnye nhọrọ ụzọ serval. Otú ọ dị, a ka nwere ụfọdụ okwu kpọmkwem maka usoro ọ bụla. Nke a bụ nkọwa.

Usoro ụzọ 1

N'ime usoro 1, anyị na-amalite site na ịmegharị akụkụ azụ (n'ime n'ime) nke workpiece wee jiri plasta mejupụta ebe ndị nwere oghere. Na-esote, ikwe ka akụkụ azụ bụrụ ihe ntụnye aka, anyị na-eji gluu na teepu nwere akụkụ abụọ iji dozie akụkụ ntụaka ahụ iji mee ka igwe dị n'ihu.

Agbanyeghị, enwere ụfọdụ nsogbu na usoro a. N'ihi nnukwu oghere backfilled n'akụkụ azụ, gluu na teepu nwere akụkụ abụọ adịghị echekwa nke ọma na workpiece. Ọ na-eduga na warping n'etiti workpiece na ihe ndị ọzọ mwepụ na usoro (a na-akpọ overcutting). Ke adianade do, enweghị nkwụsi ike nke workpiece na-eduga na ala nhazi arụmọrụ na ogbenye elu mma ụkpụrụ.

Usoro ụzọ 2

Na usoro 2, anyị na-agbanwe usoro nke machining. Anyị na-amalite na n'okpuru (n'akụkụ ebe okpomọkụ na-ekpochapụ) wee jiri nkedo azụ azụ nke oghere oghere. Na-esote, ikwe ka akụkụ ihu dị ka ihe ntụnye aka, anyị na-eji gluu na teepu nwere akụkụ abụọ iji dozie akụkụ ntụaka ka anyị nwee ike ịrụ ọrụ n'akụkụ azụ.

Otú ọ dị, nsogbu dị na usoro a yiri usoro ụzọ 1, ma e wezụga na a na-atụgharị okwu ahụ n'akụkụ azụ (n'ime ime). Ọzọ, mgbe azụ n'akụkụ nwere nnukwu hollowing backfill ebe, ojiji nke gluu na abụọ-akụkụ teepu adịghị enye elu kwụsie ike na workpiece, na-akpata warping.

Usoro usoro 3

N'ime usoro 3, anyị na-atụle iji usoro nhazi nke usoro 1 ma ọ bụ usoro 2. Mgbe ahụ, na usoro ntinye nke abụọ, jiri efere pịa jide workpiece site na ịpị ala na perimeta.

Otú ọ dị, n'ihi nnukwu mpaghara ngwaahịa, platen nwere ike ikpuchi ebe dị n'akụkụ ya ma ọ nweghị ike idozi ebe etiti etiti nke workpiece.

N'otu aka ahụ, nke a na-eme ka etiti etiti nke workpiece ka na-apụta site na warping na deformation, nke na-eduga n'ịfefe na mpaghara etiti nke ngwaahịa ahụ. N'aka nke ọzọ, usoro eji arụ ọrụ a ga-eme ka akụkụ shei CNC dị gịrịgịrị na-esighị ike.

Usoro usoro 4

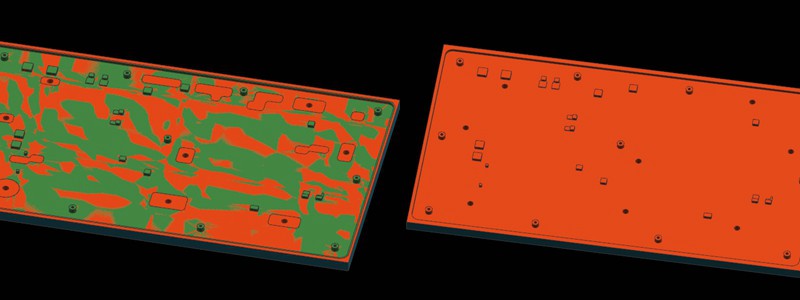

N'ime usoro 4, anyị na-eji igwe na-atụgharị azụ (n'ime ime) na mbụ wee jiri vacuum chuck tinye ụgbọ elu a na-atụgharị iji rụọ ọrụ n'ihu.

Otú ọ dị, n'ihe banyere akụkụ shei ahụ dị gịrịgịrị, e nwere akụkụ concave na convex dị n'akụkụ azụ nke workpiece nke anyị kwesịrị izere mgbe ị na-eji mmetụ agụụ. Ma nke a ga-emepụta nsogbu ọhụrụ, ebe ndị a na-ezere na-atụfu ike ịmịnye ha, karịsịa na mpaghara akụkụ anọ na gburugburu nke profaịlụ kachasị.

Dị ka ebe ndị a na-adịghị ahụkebe kwekọrọ n'akụkụ ihu (elu igwe a na-arụ n'oge a), bounce ngwá ọrụ ịkpụ nwere ike ime, na-eme ka usoro ngwá ọrụ na-ama jijiji. Ya mere, usoro a nwere ike inwe mmetụta na-adịghị mma na àgwà nke machining na njedebe elu.

Ụzọ kachasị mma na Ngwọta Ngwọta

Iji dozie nsogbu ndị a dị n'elu, anyị na-atụ aro usoro kachasị mma na ngwọta nkwụsị.

Pre-machining kposara Site-oghere

Nke mbụ, anyị kwalitere ụzọ usoro ahụ. Site na ngwọta ọhụrụ ahụ, anyị na-edozi akụkụ azụ (n'ime ime) nke mbụ na tupu igwe kposara oghere n'akụkụ ụfọdụ nke ga-emecha kpochapụ. Ebumnuche nke nke a bụ ịnye usoro nhazi na nhazi nke ọma na usoro nhazi nke na-esote.

Gburugburu Mpaghara a ga-eji igwe arụ ọrụ

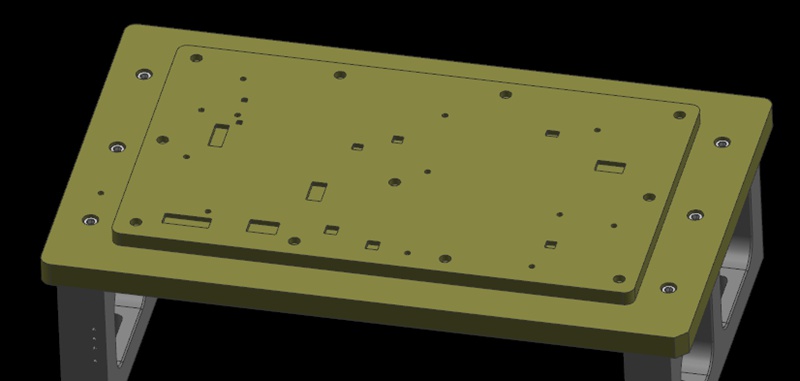

Na-esote, anyị na-eji ụgbọ elu ndị a na-emepụta ihe n'akụkụ azụ (n'ime ime) dị ka ihe eji eme ihe. N'otu oge ahụ, anyị na-echekwa workpiece site na-agafe ihe nkedo site na oghere n'elu site na usoro gara aga ma kpochie ya na efere nkwụnye. Mgbe ahụ, gbaa gburugburu ebe a na-akpọchi skru dị ka ebe a ga-arụ ọrụ.

Usoro nhazi na Platen

N'oge a na-arụ ọrụ igwe, anyị na-ebu ụzọ hazie ebe ndị ọzọ na-abụghị ebe a ga-arụ ọrụ. Ozugbo etinyere ebe ndị a, anyị na-etinye platen n'elu ebe a na-emepụta ihe (ọ dị mkpa ka a na-ekpuchi efere ahụ na gluu iji gbochie ikpochapụ elu igwe). Mgbe ahụ, anyị na-ewepụ ihe nkedo ndị a na-eji na nzọụkwụ 2 ma nọgide na-arụ ọrụ ebe a ga-arụ ọrụ ruo mgbe ngwaahịa ahụ gwụchara.

Site na usoro a kachasị mma yana ngwọta nrụnye, anyị nwere ike ijide akụkụ shei CNC dị gịrịgịrị nke ọma ma zere nsogbu ndị dị ka mgbagha, mgbagha, na ịcha oke. Ihe nkedo a na-agbanye n'elu na-ekwe ka efere nkwụnye ahụ na-ejikọta ya na workpiece, na-enye nkwado na nkwado a pụrụ ịdabere na ya. Tụkwasị na nke ahụ, iji efere mpempe akwụkwọ na-etinye nrụgide n'ebe a na-emepụta ihe na-enyere aka mee ka ọrụ ahụ kwụsie ike.

Nyocha dị omimi: Otu esi ezere ọgụ na nrụrụ?

Iji nweta ihe ịga nke ọma n'ịrụ nnukwu ụlọ nke shei nwere mgbidi chọrọ nyocha nke nsogbu ndị akọwapụtara na usoro nhazi. Ka anyị lebakwuo anya ka a ga-esi merie nsogbu ndị a nke ọma.

Akụkụ ime tupu arụ ọrụ

Na nzọụkwụ mbụ na-arụ ọrụ (na-arụ ọrụ n'ime ime), ihe ahụ bụ ihe siri ike nke nwere ike dị elu. Ya mere, workpiece adịghị ata ahụhụ site na machining anomalies dị ka deformation na warping n'oge a usoro. Nke a na-eme ka nkwụsi ike na nkenke mgbe ị na-eji ihe nkedo mbụ.

Jiri usoro mkpọchi na ịpị

Maka nzọụkwụ nke abụọ (machining ebe ebe ikpo ọkụ dị), anyị na-eji usoro mkpọchi na ịpị nke clamping. Nke a na-eme ka ike nkedo ahụ dị elu ma na-ekesa nke ọma na ụgbọ elu ntụaka na-akwado. Mkpọchi a na-eme ka ngwaahịa ahụ kwụsie ike na ọ naghị agba ọsọ n'oge usoro niile.

Ngwọta Nhọrọ: Na-enweghị Nkịtị oghere

Otú ọ dị, anyị na-ezute mgbe ụfọdụ ọnọdụ ebe ọ na-agaghị ekwe omume ịme ka ịghasa site na oghere na-enweghị usoro oghere. Nke a bụ ngwọta ọzọ.

Anyị nwere ike na-ebu ụzọ chepụta ụfọdụ ogidi n'oge machining nke agbara n'akụkụ wee tap na ha. N'oge usoro nhazi na-esote, anyị nwere ihe nkedo na-agafe n'akụkụ azụ nke ihe nrụnye ma kpochie ọrụ ahụ, wee rụọ ọrụ nke ụgbọ elu nke abụọ (n'akụkụ ebe okpomọkụ na-ekpochapụ). N'ụzọ dị otú a, anyị nwere ike mezue nzọụkwụ nke abụọ machining na otu ngafe na-enweghị ịgbanwe efere dị n'etiti. N'ikpeazụ, anyị na-agbakwunye nzọụkwụ atọ na-ejikọta ma wepụ ogidi usoro iji mezue usoro ahụ.

N'ikpeazụ, site n'ịkwalite usoro na ngwọta nkwụsị, anyị nwere ike dozie nsogbu nke warping na deformation nke nnukwu akụkụ shei dị mkpa n'oge CNC machining. Ọ bụghị naanị na nke a na-eme ka nrụpụta machining dị mma na arụmọrụ mana ọ na-eme ka nkwụsi ike na ogo elu nke ngwaahịa ahụ dịkwuo mma.